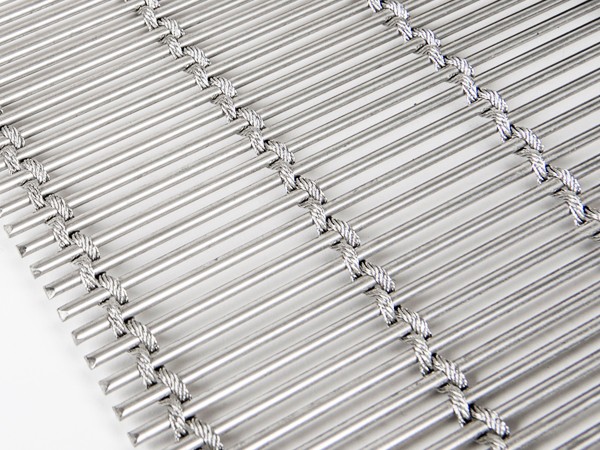

Design and Structure

The woven rod bar belt is composed of smooth, solid crossbars, typically made from heat-resistant and corrosion-resistant metal, arranged in a woven pattern and interconnected by wire strands. These interwoven rods create an open, stable mesh that supports product movement while allowing for excellent airflow and uniform heat distribution—essential for drying processes.

The design is versatile, with two edge options:

Cut Edges: Ideal for applications that require more flexibility.

Reinforced Edges: Adds durability to the belt, preventing wear and providing a longer service life under heavy usage.

Material and Temperature Resistance

Constructed from high-temperature-resistant alloys such as stainless steel, the woven rod bar belt can withstand temperatures of up to 400°C, making it suitable for demanding environments. The belt's materials are also designed to resist corrosion, which ensures consistent performance and longevity in both dry and humid conditions.

Standard Sizes and Customization

This belt can be produced in various widths, up to 3,500 mm, which enables compatibility with a wide range of industrial conveyors. The option to customize the belt width and select materials makes it adaptable to specific processing needs, from small-scale production lines to large industrial setups.

Advantages of Woven Rod Bar Conveyor Belts

Customization: Can be tailored to specific needs with variations in rod diameter, spacing, and materials to meet diverse industrial requirements.

Ventilation and Drainage: The mesh structure provides excellent ventilation and drainage, ideal for applications needing airflow or liquid drainage, like food processing and drying.

Flexible Design: The flexible structure adapts to various shapes and contours, suitable for conveyor systems navigating curves or irregular surfaces.

Temperature Resistance: With appropriate materials, these belts can withstand high temperatures, making them suitable for heat treatments and other high-temperature processes.

High Flexibility: The flexibility in the running direction significantly improves metal fatigue resistance, even at high speeds on small diameter pulleys.

Easy Cleaning and Maintenance: The open structure facilitates easy cleaning, while inspections and repairs are relatively straightforward.

Belt Types

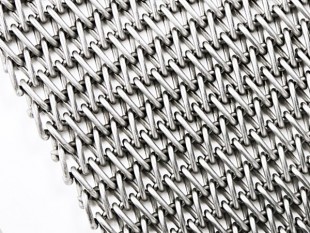

Woven Rod Bar Conveyor Belts is a simple woven wire fabric with square and rectangular grids. It is made of single wires with circular cross-section in the weft direction and one or more wire ropes in the warp direction on a heavy-duty loom.

One warp wire rope

Two warp wire ropes

Three warp wire ropes

Four warp wire ropes

Edge Availability

The weft wires are plasma-welded into groups of 2 or 3, which prevents them from shifting and protects the edges from damage.

Joining Methods

Pin-Joint

This is the preferred joining method. The belt’s leading and trailing ends are designed with pre-formed loops, allowing a pin to be inserted through them. This system enables quick and easy assembly and disassembly directly on the machine.

Endless Seam

The belt is supplied as an endless loop, with warp cables interwoven to form a seamless join. This method is ideal for applications requiring consistent openings along the belt’s length. Since this joining requires the belt to be installed from the side, it necessitates a specially designed machine setup.

Staple Fastener Clipper

This joint uses staple fasteners, allowing quick and secure assembly of the belt. The clipper-style connection is durable and can withstand various applications, making it suitable for situations where the belt may need frequent assembly and disassembly.

Specifications

Stranded Warp Cable Diameter: 0.7 – 1.2 mm

Weft Wire Diameter: 1.5 – 2.5 mm

Weft Wire Gap: 1.0 – 3.0 mm

Warp Cable Gap: 8.0 – 24.0 mm

Note: The above are general belt data, special data can be customized.

The woven rod bar belt is particularly popular in industries where products need to be conveyed and dried efficiently. Typical uses include:

Food Processing: Commonly used for drying and conveying vegetables, fruits, and mushrooms due to its gentle handling and effective drying properties.

Agriculture: Efficiently dries green fodder, hops, and tobacco, ensuring even drying without product damage.

Chemical Processing: Suitable for high-temperature chemical drying and conveying processes, where robust, corrosion-resistant materials are necessary.

Woven Rod Bar Conveyor Belts for Fish Freezing

Woven Rod Bar Conveyor Belts for Baking

Woven Rod Bar Conveyor Belts for Dewatering

Woven Rod Bar Conveyor Belts for Pasta Drying

+86-15369679157

+86-15369679157