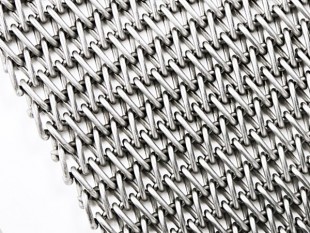

Ladder Conveyor Belts

Ladder Conveyor Belt is a simple but effective style of conveyor belt, generally used belt for common processes and common product loads. Its open design provides efficient operation with minimum maintenance as well as facilitating easy and thorough cleaning. Its lightweight and basic configuration make it a very economic and cost-effective style of belting for many different environments. The ladder belts are used in production processes with temperatures of -100ºC to +450ºC in food and other industries.

Ladder Conveyor Belts

Ladder Conveyor Belts

Ladder Conveyor Belt Enquiry Form

Ladder Conveyor Belt Enquiry Form

Beijing PFM SCREEN Mesh Conveyor Belt Product Catalog 2024

Beijing PFM SCREEN Mesh Conveyor Belt Product Catalog 2024

+86-15369679157

+86-15369679157