Wire Mesh Lehr Belts are specialized conveyor belts designed for the glass industry's annealing and decorating processes. They ensure the smooth and stable transportation of glass containers through lehr furnaces, where controlled cooling relieves internal stresses and enhances product durability.

For over 30 years, PFM SCREEN has been a global leader in designing and manufacturing premium Wire Mesh Lehr Belts, essential for the glass industry’s annealing and decorating processes. Our belts ensure the safe, stable conveyance of glass containers through extreme temperatures, enabling precise stress relief and enhancing product durability. Trusted worldwide, PFM SCREEN’s lehr belts combine innovative engineering with uncompromising quality to deliver unmatched performance in the most demanding environments.

Key Features

• Smooth Conveying Surface: Provides stability for glass products during transit.

• Minimal Belt Stretch: Ensures longer belt life and consistent performance.

• Accurate Tracking: The balanced weave design offers precise tracking, reducing maintenance needs.

• Customizable Widths: Available in widths exceeding 5 meters to accommodate various industrial requirements.

Construction and Materials

Construction

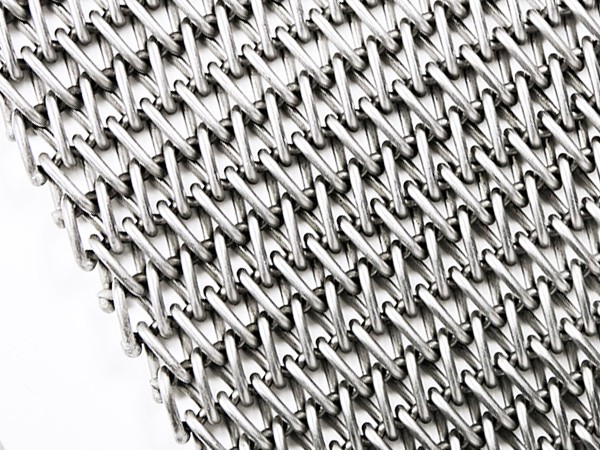

• Balanced weave structure, comprising alternating right and left-hand flattened spirals connected by crimped rods. This design ensures locked-in spirals for straight tracking and product stability. Edges are welded for added durability.

• Compound weave structure, balanced spiral belt with multiple spirals and cross rods per pitch, resulting in minimal apertures and a flat surface. This structure ensures a close and flat mesh, ideal for conveying very small items.

Materials

• Chrome Molybdenum Steel: Suitable for high-temperature applications.

• 430 Stainless Steel: Offers corrosion resistance and durability.

• 304 Stainless Steel: Provides excellent corrosion resistance and strength.

These materials enable the belts to withstand operating temperatures up to 1200°C, depending on the specific material used.

Belt Types

Round Wire Spirals Lehr Belts

Flattened Wire Spirals Lehr Belts

Compound Weave Lehr Belts ( Round or Flattened Wire )

Edge Availability

Lehr Belts with Welded Edge

The most common and cost-effective edge finish. Welding both the coil and crimp wires eliminates cut wire ends.

Specifications

Balanced weave structure

A: Spiral Wire Pitch (mm) B: Spiral Wire Diameter (mm)

C: Cross Rod Pitch (mm) D: Cross Wire Diameter (mm)

Compound weave structure

A: Coil Pitch (mm) C: Cross Wire Pitch (mm)

B: Coil Wire Diameter (mm) D: Cross Wire Diameter (mm)

E: Number of Cross Wires per Spiral Coil (mm)

|

Material

|

Carbon Steel, 430 Stainless Steel, 304 Stainless Steel, 314 Stainless Steel, etc.

|

|

Coil wire diameter

|

Round wire: 1 to 4 mm

Flat wire: 1.2 x 0.8 mm to 4 x 2 mm

|

|

Cross Wire diameter

|

1.5 to 5 mm

|

|

Cross wire pitch

|

6.5 to 40 mm

|

|

Coil wire pitch

|

3 to 33 mm

|

|

Belt width

|

35 mm to 5000 mm

|

|

Operating temperature

|

Carbon steel: 538°C

Stainless steel: 1120°C

Nickel Chrome: 1200°C

|

Wire Mesh Lehr Belts are primarily used in:

• Glass Annealing: Facilitating controlled cooling of glass products to enhance strength.

• Decorating Processes: Ensuring stable transport during surface treatments of glass containers.

• Baking Ovens: Suitable for high-temperature baking applications.

• High-Temperature Conveyance: Ideal for environments requiring heat-resistant conveyor solutions.

+86-15369679157

+86-15369679157